AtlantechUSA’s Through-Hole Mounting Solutions are designed to deliver secure and reliable component attachment for high-durability electronic assemblies. Ideal for applications requiring robust connections, our through-hole mounting services provide precision placement and strong mechanical bonds, ensuring longevity and performance even in demanding environments. Using advanced equipment and decades of expertise, we support both high-volume production and specialized projects, offering solutions that meet the quality and reliability standards crucial for industries such as automotive, aerospace, and industrial electronics.

Our through-hole mounting solutions ensure precise component placement and strong mechanical bonds, ideal for applications demanding high durability and reliability.

Using state-of-the-art equipment, we deliver accurate and consistent through-hole mounting, enhancing performance and reducing production errors

We customize our through-hole solutions to meet the rigorous standards of industries like automotive, aerospace, and industrial electronics, ensuring long-lasting connections in critical applications.

- Through Hole Mounting

Panasonic AV132

The AV high-speed axial lead component insertion machine features a compact design and 30,000 cph performance. The dense supply unit configuration is available in 40 or 80 component inputs with optional jumper wire and accommodates both ammo pack and reel. Quicken changeover with the dual partition setup and set up the next job while the current one is being produced.

Panasonic RG131

A high-density radial lead component insertion machine, the RG131 with guide pin system provides stable, high-density insertion at 14,400 cph (0.25s/component). This through-hole machine inserts components with a pitch range of 2.5mm, 5.0mm or 7.5mm and allows for 40 or 80 component inputs - a wide component range in a compact footprint with a low cost of ownership. Full auto-recovery corrects insertion errors while the part exhaust detection system allows for proactive part replenishment and promotes continuous productivity.

Panasonic RL132 Radial Through-Hole Inserter

Panasonic's RL132 high-speed radial lead component insertion machine offers generation-ahead technology in a spatially-efficient footprint. The RL132's combination of 25,700cph (.14s/component) insertion rates, board processing sizes up to 650 x 381mm, a 33% reduction in PCB transfer time, up to 18% reduction in electrical and air consumption per insertion and an improved perishable parts lifespan results in a very low cost of ownership.

Panasonic JV131 Jumper Wire Inserter

The JV131 jumper wire insertion machine is industry-leading with a tact time of 45,000 cph (0.08s/component). Its high-speed insertion of wire from bulk (drum or reel) into printed circuit boards includes variable insertion pitch settings - from 5mm through 31mm in 1/100mm increments. The compatibility of the JV131 also accepts spare parts and NC programs from previous generation Panasonic insertion equipment as well as industry-standard loader/unloader units.

Panasonic NPM-VF

Panasonic designed the NPM-VF odd-form solution to address increasing global labor costs and manual assembly complexity. The new platform, built from the award-winning NPM Platform, introduces several innovative solutions to reduce labor requirements and cost, while boosting productivity, enhancing versatility, and helping ensure quality through-hole and odd-form component insertions.

Panasonic

At Panasonic Connect, we harness our decades of expertise and listen to our customers to provide innovative, forward-looking solutions that help you reach specific goals and meet evolving industry demands. What sets us apart as a leading technology provider is our ecosystem of partners, innovators and integrators that we work with to connect customers to the right technologies that move your business forward.

- Wave Solder

Kurtz Ersa Powerflow

With the POWERFLOW system supplier Ersa presents a high-performance wave soldering system with flexible soldering bath technology at attractive value-for-money. Technologically, the system is state of the art and includes process-relevant components made in Germany as motors, control units, nozzles – final assembly takes place in the Chinese production site Zhuhai.

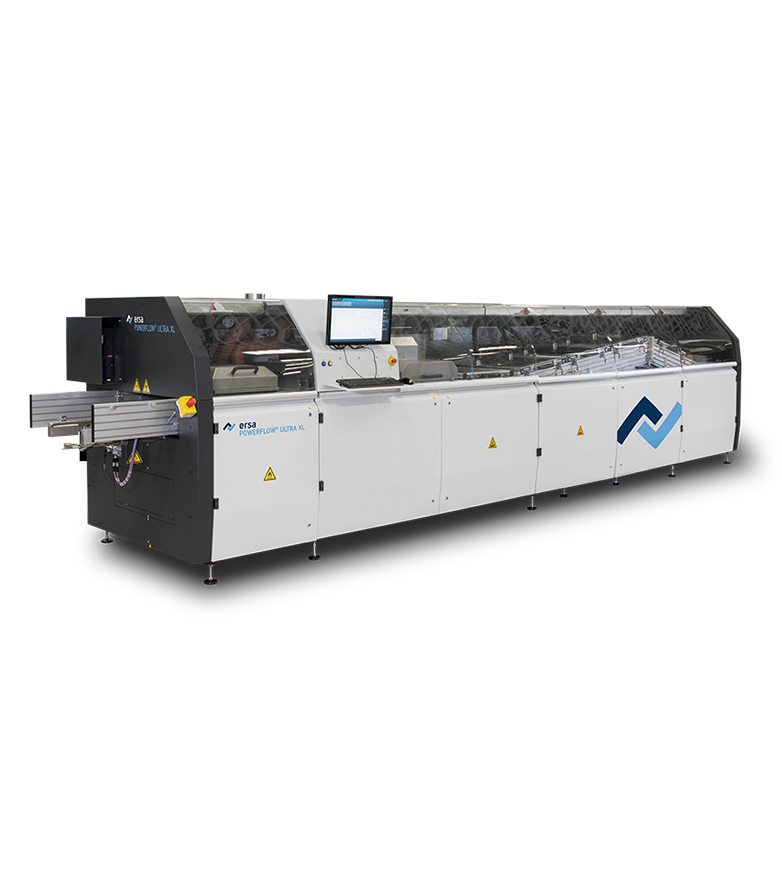

Kurtz Ersa Powerflow Ultra XL

With the POWERFLOW ULTRA XL wave soldering system, Ersa presents the ultimate solution for demanding lead-free wave soldering processes. The high-end system is based on a machine concept with numerous future-oriented and intelligent solutions that provide the user with high added value.

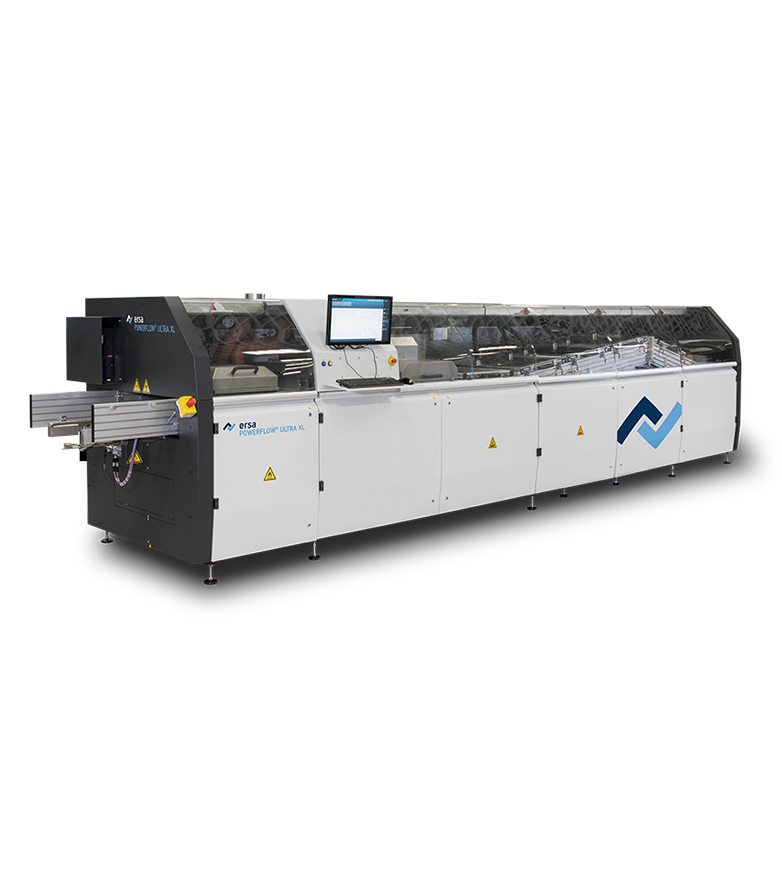

Kurtz Ersa Powerflow Ultra XXL

With the POWERFLOW ULTRA XXL wave soldering system, Ersa presents the ultimate solution for demanding lead-free wave soldering processes. The high-end system is based on a machine concept with numerous future-oriented and intelligent solutions that provide the user with high added value.

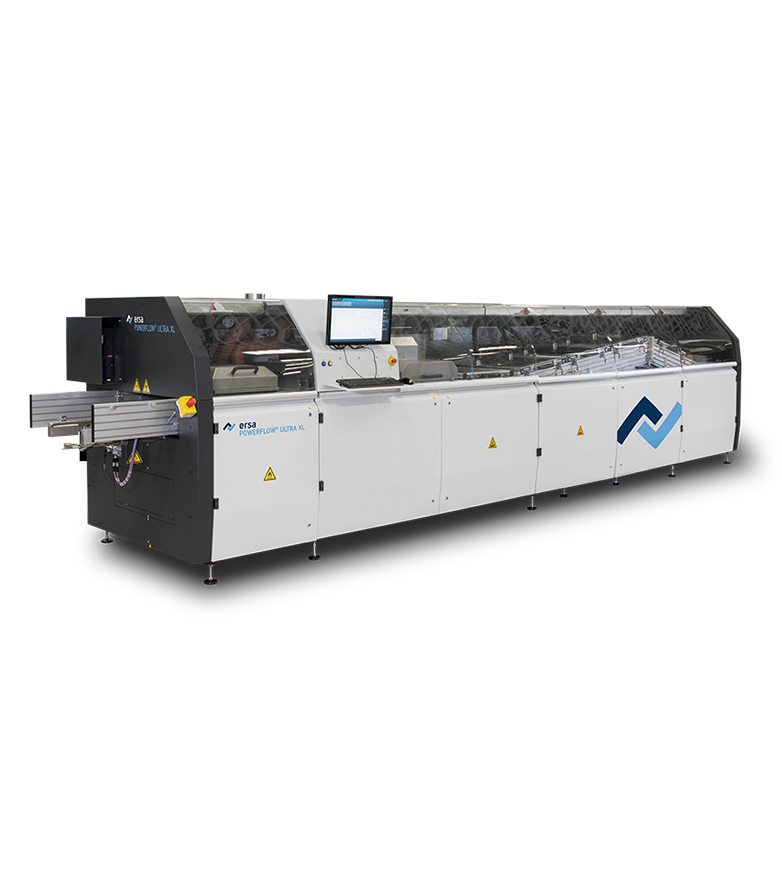

Kurtz Ersa Powerflow Ultra

With the POWERFLOW ULTRA Wave Soldering System, Ersa presents the ultimate solution for demanding lead-free wave soldering processes. This high-end product is based on a system concept with numerous future oriented and intelligent solutions, which will provide substantial added value to its users.

Kurtz Ersa Powerflow Pro

With the Ersa nitrogen-atmosphere wave soldering system POWERFLOW PRO, Ersa presents a basic system for demanding, cost-optimized wave soldering processes. The system focuses on proven machine concepts and offer future oriented and innovative solutions, which provides to its user an optimized process.

Kurtz Ersa Group

We are a globally active machine manufacturer, founded in 1779 and owner-managed in the 7th generation. As a technology and market leader in the fields of Electronics Production Equipment, Moulding Machines and Automation we optimize the manufacturing processes of our customers.

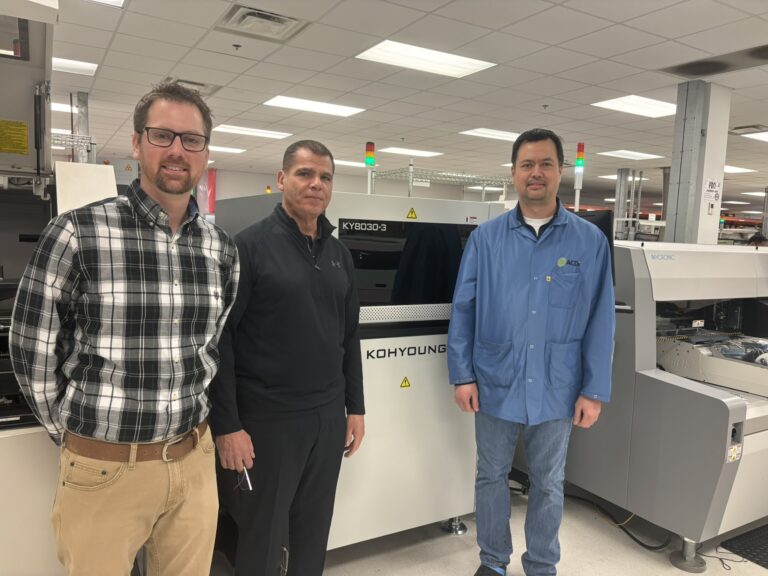

Your Partner for High-Quality Through-Hole Assembly

- Selective Soldering

Kurtz Ersa VERSAFLOW 4/55

The ultimate in selective soldering! With the VERSAFLOW 4, world market leader Ersa has made inline selective soldering even better.

Kurtz Ersa VERSAFLOW 4 XL

VERSAFLOW 4 XL is designed for PCB sizes of up to 610 x 1,200 mm. This selective soldering system provides a revolutionary new dimension of flexibility and application variety – at highest soldering quality, of course!

Kurtz Ersa VERSAFLOW 3/66 XL

Modular machine platform for processing PCBs with a maximum length of 3,000 mm.

Kurtz Ersa VERSAFLOW 3/66

Modular machine platform for highly flexible inline selective soldering of XL boards.

VERSAFLOW 3/45

The VERSAFLOW 3/45 is the first in-line selective soldering machine with dual track transport. Highest flexibility and highest throughput can be realised with the smallest possible required space.

VERSAFLOW 3/35 GLOBAL EDITION

Completely configured Ersa soldering machines with the world´s leading selective soldering technology - available within four weeks!

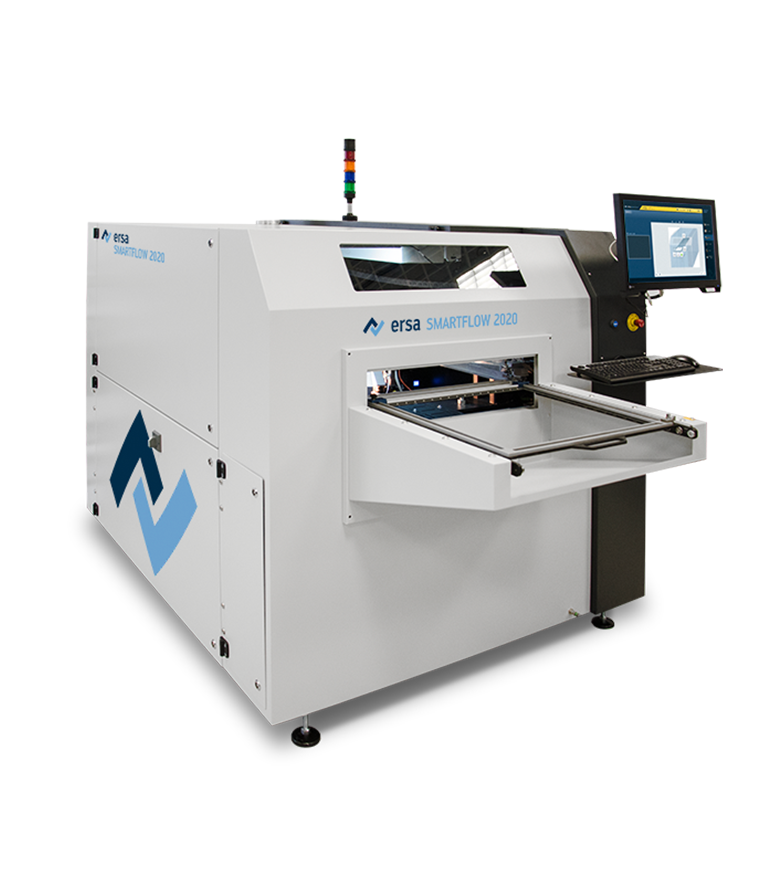

Kurtz Ersa SMARTFLOW 2020

The little big one from Ersa in selective soldering: compact without compromises, extremely smart! Winner of the GTI Award 2015.

Kurtz Ersa EXOCELL

Selective Soldering System in-line and off-line: uncompromising throughput - flexible layout.

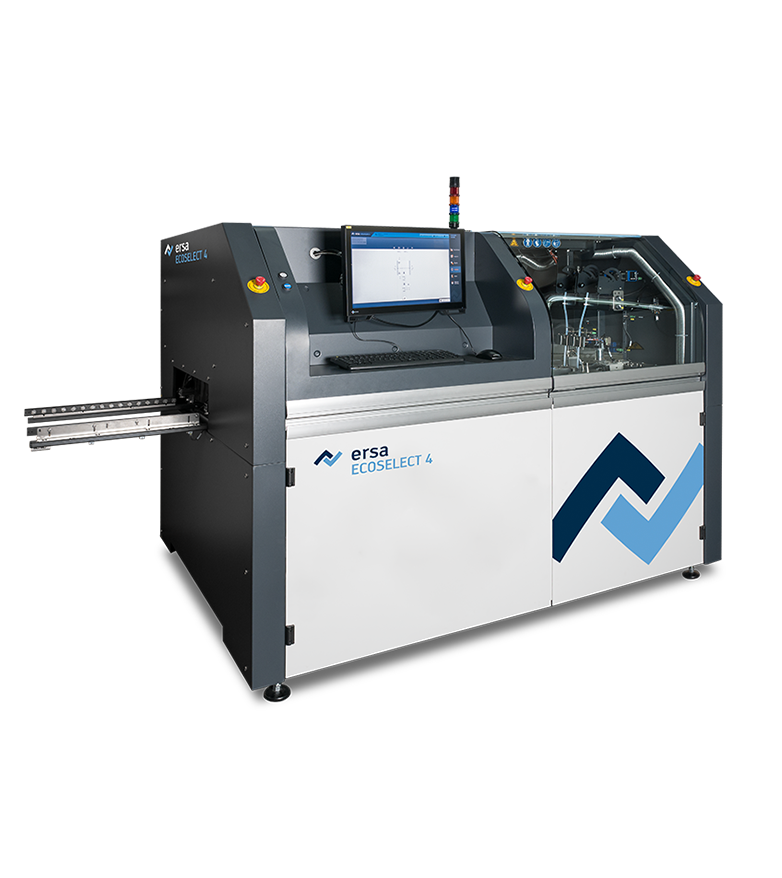

Kurtz Ersa ECOSELECT 4

Selective Soldering System in-line and off-line: uncompromising throughput - flexible layout.

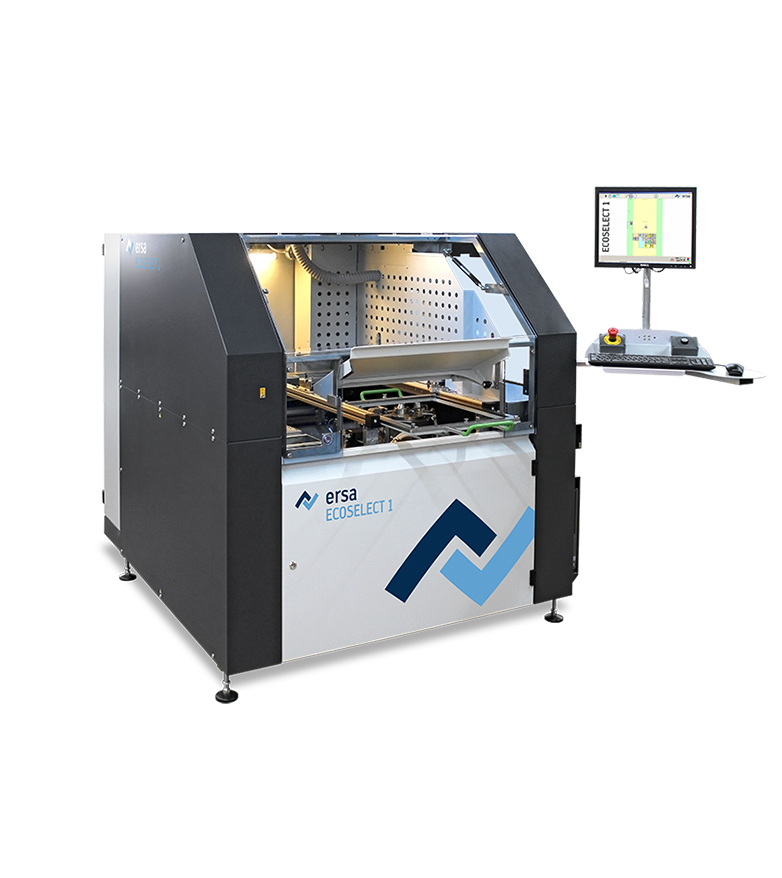

Kurtz Ersa ECOSELECT 1

Small Selective Soldering System with outstanding technology.

- Our Principles

Guided by Excellence: Principles that Drive Innovation and Integrity

Industry Leaders Committed to Excellence

Our principles center on setting the benchmark for innovation and expertise in the electronics manufacturing industry. With decades of experience, we leverage our deep knowledge and strategic partnerships to deliver high-quality, reliable solutions that drive industry progress.

Pioneering the Path to Smart Manufacturing

At the forefront of technological advancements, we prioritize smart manufacturing principles that integrate automation, real-time data, and IoT technology. Our approach ensures our clients stay competitive in a rapidly evolving landscape, achieving efficiency, flexibility, and adaptability in every production process.

Quality Assurance for Reliable Manufacturing

Quality assurance is at the heart of our operations. Our commitment to rigorous standards and continuous improvement guarantees that every product meets the highest levels of reliability and durability. From design to delivery, our focus on quality ensures consistent, dependable results across all manufacturing stages.

- Electrical Test

TestStation Multi-Site Inline

Teradyne’s TestStation Multi-Site systems deliver 2-4X greater test capacity, delivering 200-400% greater productivity, and 40-50% lower total cost of test compared to a conventional single site system.

TestStation Automated Inline Handler | In-Circuit Test Solution

Teradyne’s High-Speed Inline Automated Board Handler with TestStation Multi-Site Test Insert is designed for productivity, fast change-over, and low operating cost. Our in-circuit test solution fits seamlessly into automated production lines to provide “hands-off-lights-out” operation.

TestStation Rackmount

TestStation Rackmount (TSR) is designed for easy integration into high-volume automated manufacturing lines. This solution is a collection of specifically designed hardware modules that can be easily integrated into standard or custom automation handling equipment.

TestStation Multi-Site Offline

Teradyne’s TestStation Multi-Site Offline provides true parallel or asynchronous test, delivering 200-400% greater productivity, and 40-50% lower cost of test. This test solution features 2,560 test point capability in a footprint under 1 square meter.

TestStation LH

The TestStation LH in-circuit test system is a lower-cost, small footprint, feature scalable version of Teradyne’s popular, award winning TestStation product family. TestStation LH features SafeTest protection technologies for accurate, reliable and safe testing of the lowest low-voltage technologies.

TestStation LHS

The TestStation LHS in-circuit test system is a lower-cost, small footprint, feature scalable version of Teradyne’s popular, award winning TestStation product family. Compatible with existing TestStation LH fixtures.

TestStation LX

The TestStation LX is a powerful in-circuit test solution providing high-volume electronics manufacturers with reliable, high-quality test for the latest printed circuit board assembly technologies.

TestStation LX2

The TestStation LX2 is Teradyne’s largest pin count in-circuit test system. Configurable up to 15,360 pins utilizing UltraPin II 128HD pin cards for testing large, complex, and heavily-integrated printed circuit board assemblies.

TestStation ICT

The TestStation is Teradyne’s flagship in-circuit test system optimized for complex, highly integrated boards and features award-winning SafeTest protection technologies. The TestStation has a test point range of 256 to 3,840 pins.

- Rework and Inspection

Kurtz Ersa HR 600/3P

Precise: automatic rework for extremely fine and small components up to 01005.

Kurtz Ersa HR 600/2

Automatic: automatic desoldering, placement and soldering of SMT components.

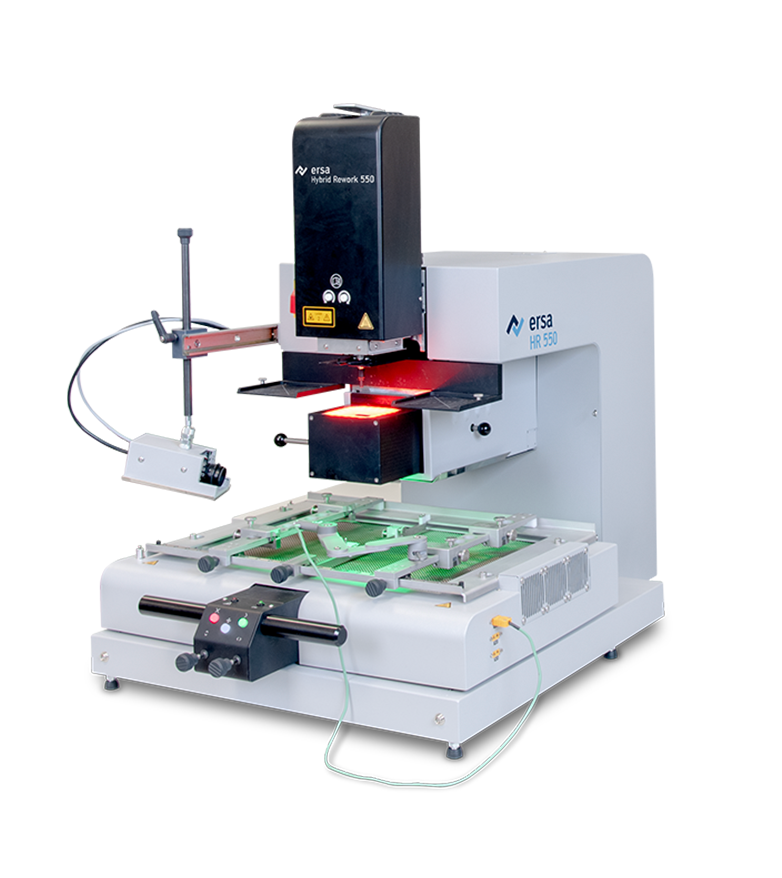

Kurtz Ersa HR 550

Visually leading: guided rework with high-performance optical system and flexible heating technology.

Kurtz Ersa HR 550 XL

Large and flexible: guided rework for large boards up to 530 x 530 mm.

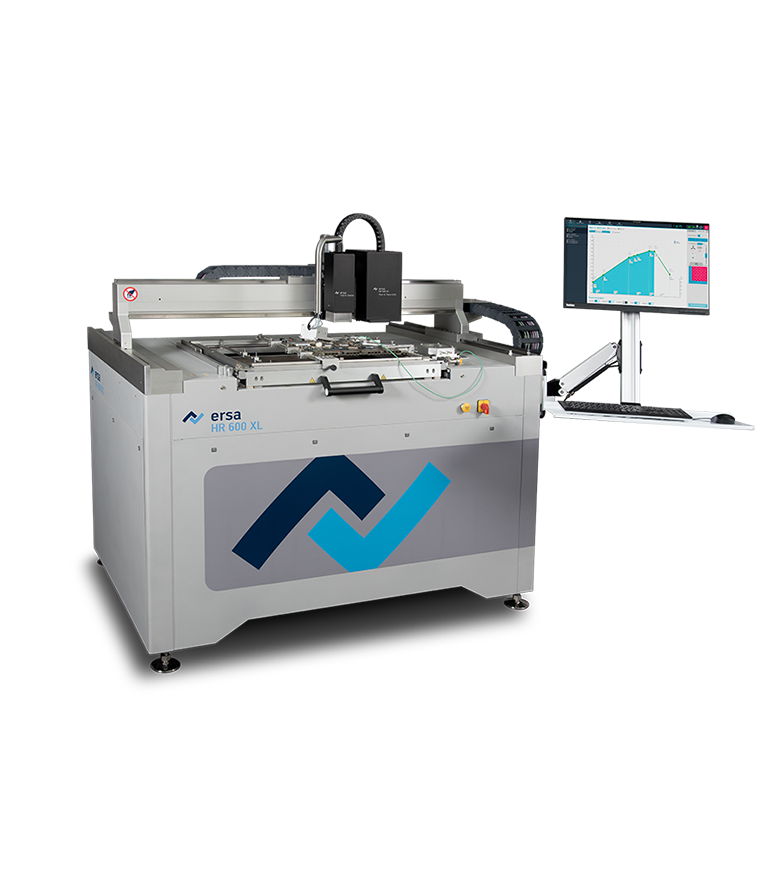

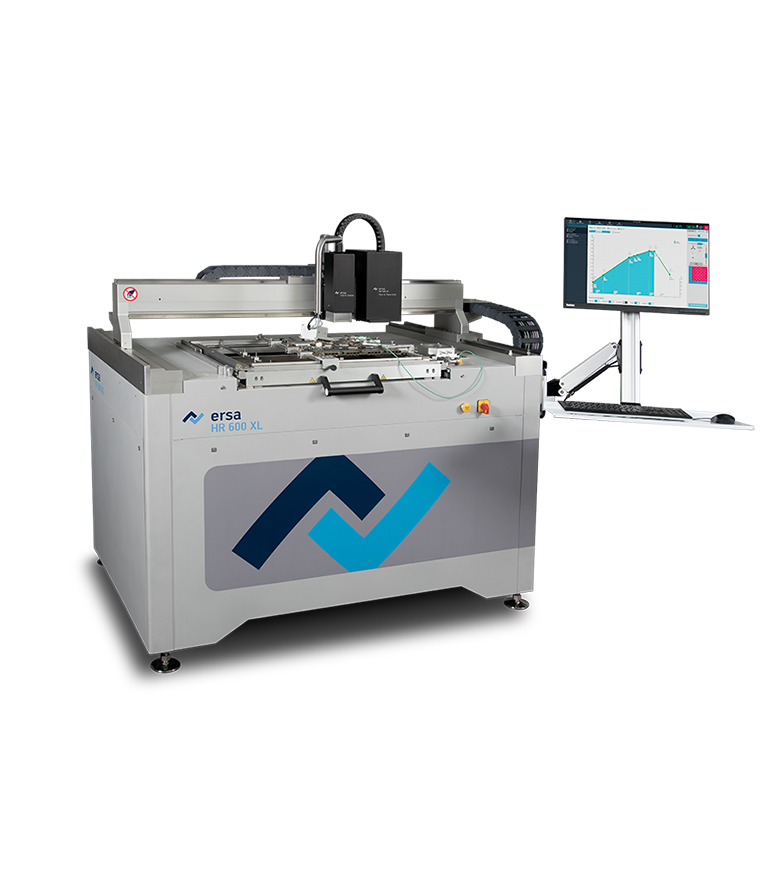

Kurtz Ersa HR 600 XL

Big and precise: automatic repair of complex assemblies up to 625 x 625 mm.

Kurtz Ersa HR 500

Budget oriented: flexible desoldering, placement and soldering of SMT components.

Kurtz Ersa IR 550

Highly flexible IR Rework System with precise component placement

Kurtz Ersa HR 200

Out of the Box: Compact Hybrid Rework Station without Software.

Kurtz Ersa HR 100

Non-contact gentle: Rework hand-guided or stationary.

Kurtz Ersa Ersa SCAVENGER

Non-contact solder removal for HR 550 and HR 550 XL.

Kurtz Ersa RPC 500

Controlled processes: reflow process camera for observation with 70x enlargement.

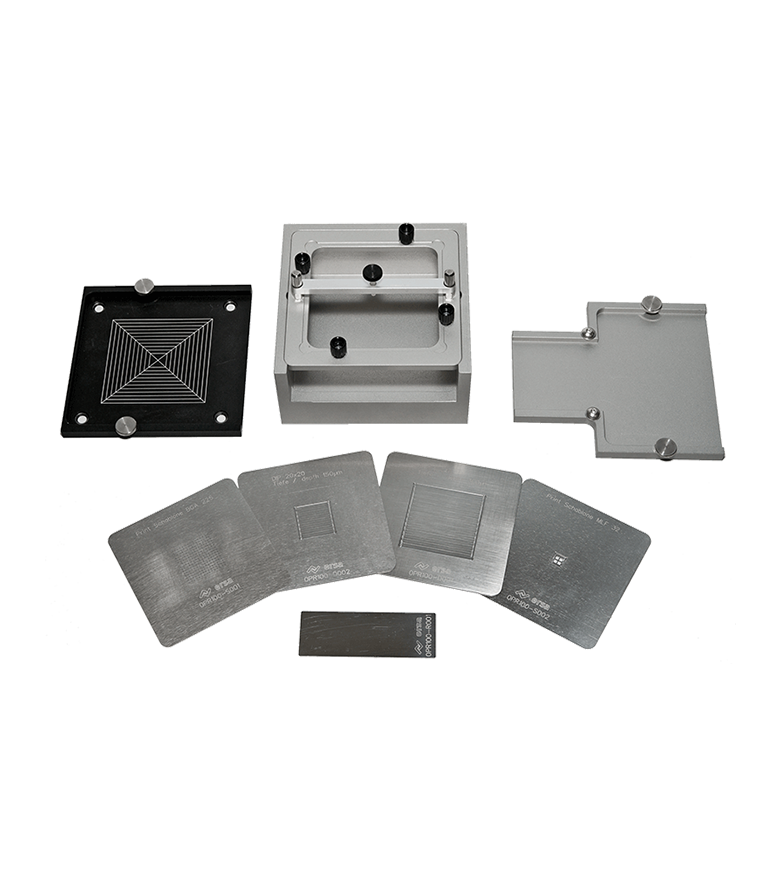

Kurtz Ersa Dip & Print Station

Well prepared: Defined flux or solder paste application during rework.

Kurtz Ersa Ersa VERSAGUIDE

Avoiding assembly errors through optical control: VERSAGUIDE is a system for support and control during PCB assembly or assembly work. This helps to avoid assembly errors and at the same time saves costs for time-consuming rework.

Principles that Drive Manufacturing Excellence

Your Vision, Our Expertise: Tailored Solutions for Every Need.

For a customized quotation and additional information on how our solutions can enhance your manufacturing process, please contact us today. Our team is ready to discuss your specific needs, provide expert guidance, and help you select the best options to achieve optimal results for your project. Reach out to explore how we can support your goals with tailored solutions and industry-leading expertise.