As the electronics industry continues to evolve, the demand for increased efficiency, precision, and speed in manufacturing processes is greater than ever. Automation has become essential in meeting these demands, enabling companies to produce complex products quickly, reliably, and at a lower cost. From printed circuit boards (PCBs) to microelectronics, automation enhances nearly every aspect of production, driving competitiveness and innovation within the electronics manufacturing sector.

Why Automation Matters in Electronics Manufacturing

1. Enhanced Precision and Consistency

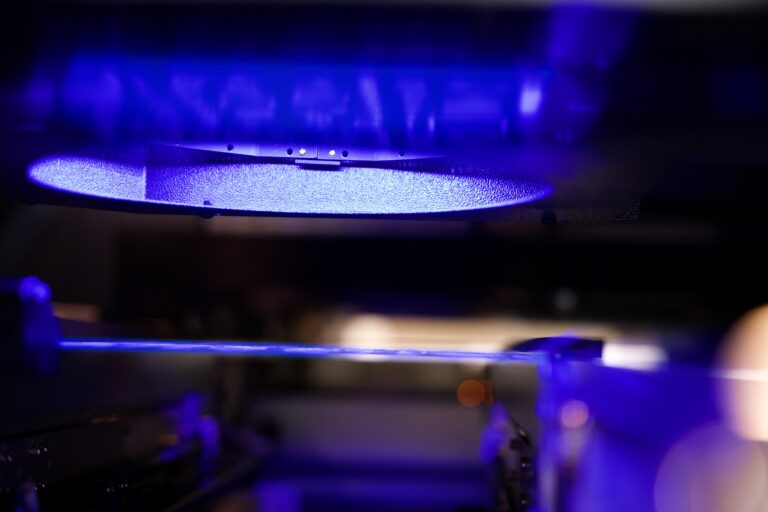

Electronics manufacturing involves intricate components and high-density assemblies where precision is key. Automated processes ensure that every step—from soldering to component placement—is executed with a high level of accuracy. Machines operate with minimal variation, resulting in consistent quality across large production runs. This consistency is especially valuable for applications in fields like automotive, medical devices, and aerospace, where even minor defects can impact product performance and safety.

2. Increased Efficiency and Speed

Manual assembly processes can be time-consuming, particularly for high-volume production. Automation allows manufacturers to significantly reduce production times while maintaining or even improving quality. Robotic assembly systems can work continuously, processing thousands of units in the time it would take for a manual team to complete a fraction of the work. This rapid production cycle enables companies to meet tight deadlines, reduce lead times, and quickly adapt to fluctuating market demands.

3. Reduced Costs

While the initial investment in automation technology can be high, the long-term cost savings are substantial. Automated systems help reduce labor costs, minimize material waste, and lower the number of defective units, ultimately decreasing overall production costs. Additionally, automation reduces the risks of costly rework and warranty claims, as fewer errors are introduced in the production process. With lower overhead costs, companies can price their products more competitively while maintaining profit margins.

4. Improved Safety and Employee Productivity

Electronics manufacturing often involves tasks that can be repetitive, delicate, or potentially hazardous. Automation reduces the need for workers to perform repetitive or dangerous tasks, lowering the risk of injury and fatigue. This not only creates a safer work environment but also allows employees to focus on more complex and value-added activities, such as quality control, process improvement, and maintenance. The result is a workforce that is more engaged and productive.

5. Data-Driven Insights for Continuous Improvement

Today’s automation systems are equipped with sensors and data-collection tools that provide real-time feedback on production performance. This data enables manufacturers to monitor metrics such as equipment efficiency, yield rates, and defect occurrences. With these insights, companies can make informed adjustments to optimize processes, anticipate maintenance needs, and continuously improve product quality. The ability to collect and analyze data is a cornerstone of Industry 4.0, enabling electronics manufacturers to operate smarter and stay competitive.

Embracing Automation: The Path Forward for Electronics Manufacturers

Automation has become a strategic necessity in the electronics manufacturing industry, driving quality, speed, and cost-efficiency to new heights. As technological advancements continue to enhance the capabilities of automated systems, companies that adopt these technologies stand to gain significant competitive advantages. By reducing reliance on manual processes and embracing automation, electronics manufacturers are better equipped to deliver high-quality products, keep pace with market demands, and innovate for the future.

For companies in the electronics industry, now is the time to evaluate the role of automation in their operations and explore solutions that can enhance their capabilities. At AtlantechUSA, we are committed to providing customized automation solutions that meet the unique needs of our clients. Our expertise helps electronics manufacturers integrate automated processes seamlessly, ensuring they reap the full benefits of this transformative technology.