Our inspection systems, including AOI, X-ray, and solder paste inspection, deliver unparalleled accuracy, meticulously evaluating each component and assembly to ensure optimal performance.

By identifying defects at the earliest possible stage, our solutions minimize rework and prevent costly delays, keeping production efficient and reducing waste.

With rigorous inspection processes, we guarantee that every product meets or exceeds industry standards, supporting reliable, high-quality output and bolstering customer satisfaction.

- Solder Paste Inspection

Koh Young KY8030-2

The World’s Best-selling Full 3D Solder Paste Inspection. Best-in-class measurement accuracy and inspection reliability. Solves shadow problems by utilizing 2-way projection. Provides accurate inspection data with real-time PCB warp compensation. Provides user-friendly software interface. Full 3D data-based process optimization solution: Realization of industry 4.0 / smart factory. Realizes real-time process optimization through powerful SPC analytics. Provides a powerful printing process optimization tool. Good value model for a variety of production environment

Koh Young KY8030-3

World-Fastest Full 3D Solder Paste Inspection. The industry’s fastest full 3D measuring inspection solution. Solves shadow problems by utilizing 2-way projection. Full 3D foreign material inspection for the entire PCB. Provides accurate inspection data with real-time PCB warp compensation. Full 3D data-based process optimization solution: Realization of industry 4.0 / smart factory. Realizes real-time process optimization through powerful SPC analytics. Provides a powerful printing process optimization tool. Leading model for high-speed mass production line.

Koh Young aSPIre 3

World-Best Performance 3D Solder Paste Inspection. Industry-leading measurement accuracy and inspection reliability. Perfect solution to eliminate shadow problems, base plane settings, and problems with projection direction. Full 3D foreign material inspection solution for the entire PCB. High productivity through the highest accuracy. Full 3D data-based process optimization solution: Realization of industry 4.0 / smart factory. Real-time process optimization through powerful SPC analytics. Maintain optimal equipment status with the embedded self-diagnosis function. The model with the best specification, suitable for variety of production environments.

Koh Young America

Koh Young America is a branch of South Korean-based Koh Young Technology, which was formed by Dr. Kwangill Koh on April 25, 2002. We share our headquarters’ vision to lead the smart revolution and hasten the evolution of industrial innovations for society.

- Automated Optical Inspection

Koh Young Technology Neptune C+

Revolutionary True 3D In-line Dispensing Process Inspection (DPI) with a Thickness Measurement Solution based on Patented Technologies.

Koh Young Technology Zenith UHS

The Fastest True 3D Automated Optical Inspection Solution. High-speed full 3D A01 that brings about a revolution in SMT process management. Perfect Inspection Performance with True 3D - only solution in the industry to set inspection criteria according to IPC-61 0 standards. Performs defect diagnosis through measurement-based data and eliminates the causes of possible errors. Powerful 3D Solder Joint Inspection. Perfect PCB Warp Compensation Solution. Whole Board Foreign Material Inspection (WFMI). Al-powered 3D Geometry-based Auto-Programming (KAP). Extended Inspection Coverage for High Height Inspection (Optional). KSMART Solutions: Full 3D Measurement-based Process Control System.

Koh Young Technology Zenith LiTE

With the POWERFLOW ULTRA XXL wave soldering system, Ersa presents the ultimate solution for demanding lead-free wave soldering processes. The high-end system is based on a machine concept with numerous future-oriented and intelligent solutions that provide the user with high added value.

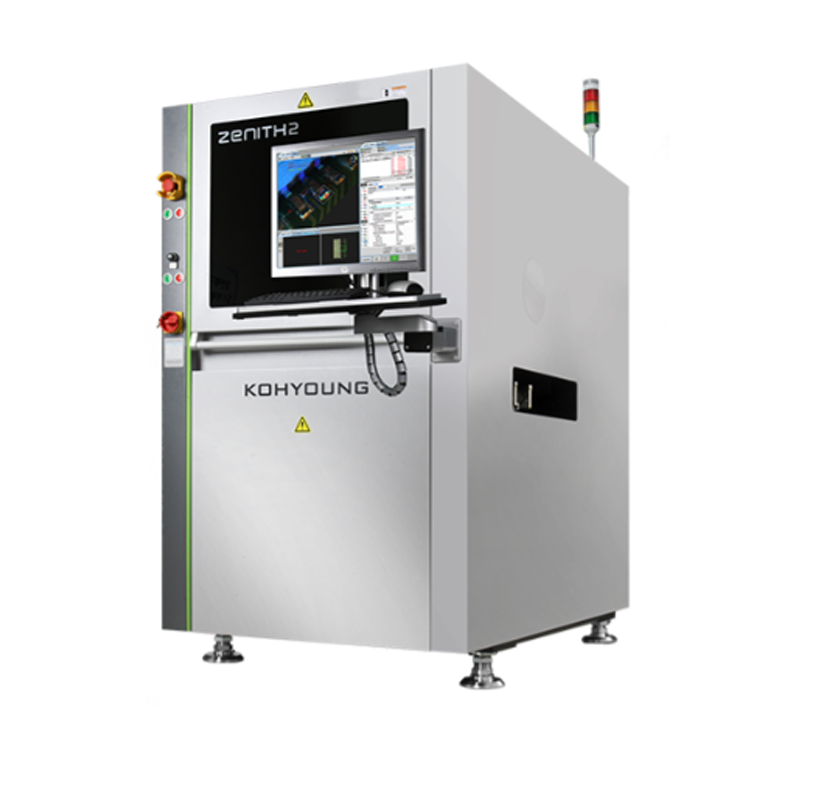

Koh Young Technology Zenith 2

Revolutionary True 3D A01 with Incomparable Inspection Capabilities. Best-in-Class 3D Measurement Capability. Extended Inspection Capabilities with a 3D Side-Camera Solution. Extended Inspection Coverage for High Height Inspection. Whole Board Foreign Material Inspection (WFMI). Al-powered 3D Geometry-based Auto-Programming (KAP). Enhanced Auto-Verification Capabilities for Low TCoO. KSMART Solutions: Full 3D Measurement-based Process Control System.

Koh Young Technology Zenith Alpha

The Foremost True 3D A01 Solution, powered by Al. Enhanced 3D Measurement Capabilities with Koh Young's Proprietary Al Technology. High Speed Suitable for Demanding Production Line. Lowest Total Cost of Ownership. Extended Inspection Coverage for High Height Inspection (Alpha HS+). Al-powered 3D Geometry-based Auto-Programming (KAP). KSMART Solutions: Full 3D Measurement-based Process Control System.

Koh Young Technology Zenith F

Industry's Best-in-Class Full 3D A01 Solution. True 3D Inspection Performance. Perfect Solution for varied Production Challenges for FPCB Assembly Process. Perfect PCB Warp Compensation Solution. Al-powered 3D Geometry-based Auto-Programming (KAP). KSMART Solutions: Full 3D Measurement-based Process Control System.

- X-Ray Failure Analysis

Scienscope X-Scope 1800

The X-Scope 1800 X-Ray Inspection System is an entry level machine with high level features.

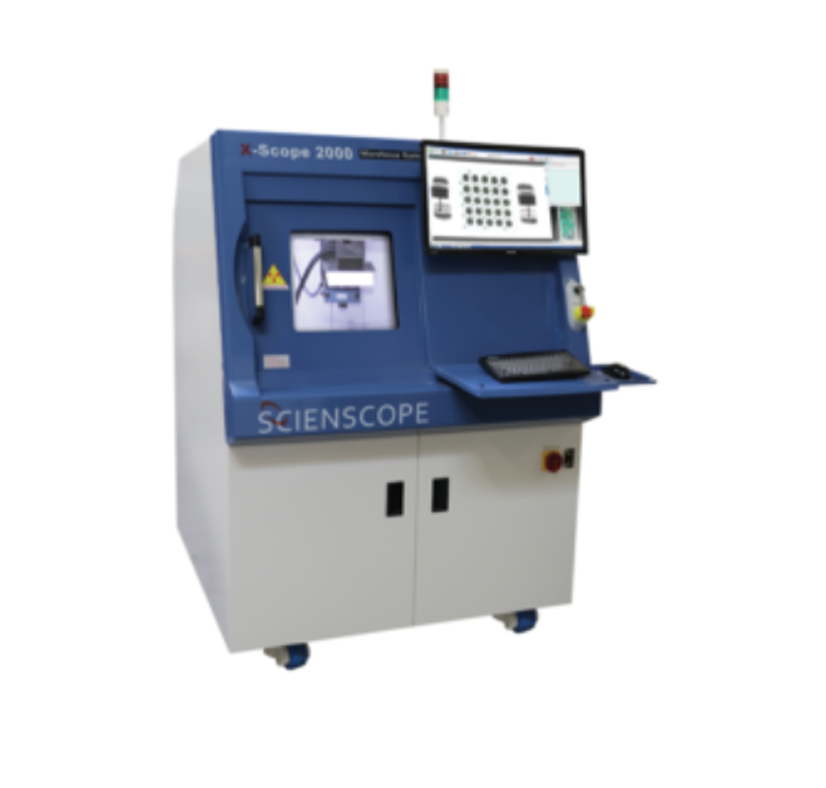

Scienscope X-Scope 2000

The X-Scope 2000 X-Ray Inspection System is a full featured high-performance x-ray inspection instrument with an unbeatable price to performance ratio which includes all of the advanced features you would expect to find on a much more expensive x-ray inspection system.

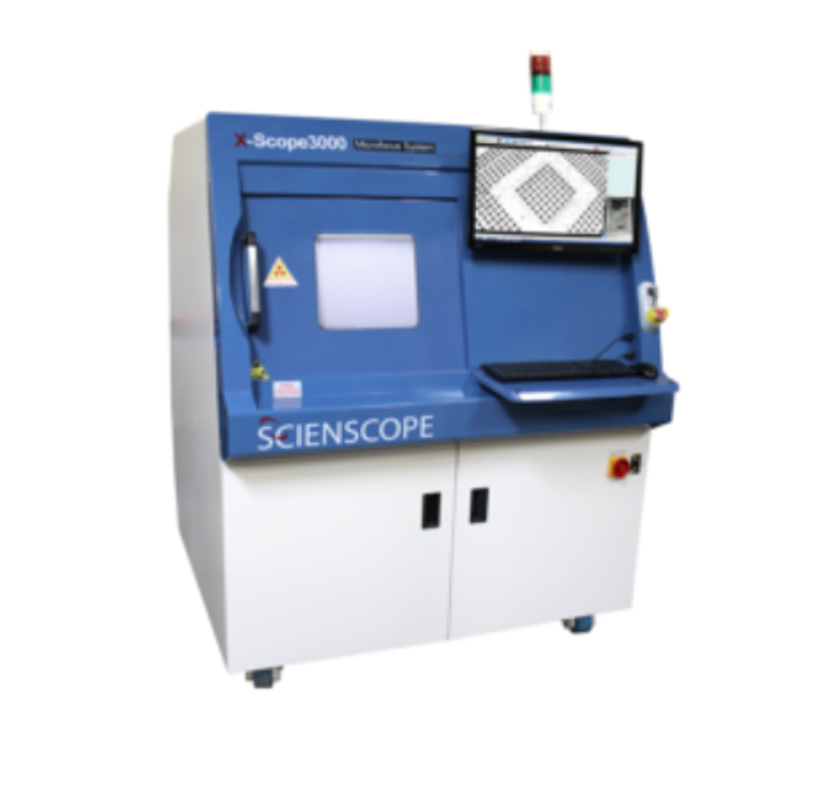

Scienscope X-Scope 3000

The X-Scope 3000 X-Ray Inspection System is the latest addition to the X-Scope platform.

Scienscope Xspection 6000

The X-Spection 6000 is our most Technologically Advanced X-Ray Inspection System. As with all X-SCOPE platforms, it includes every advanced s/w tool required for a wide variety of applications.

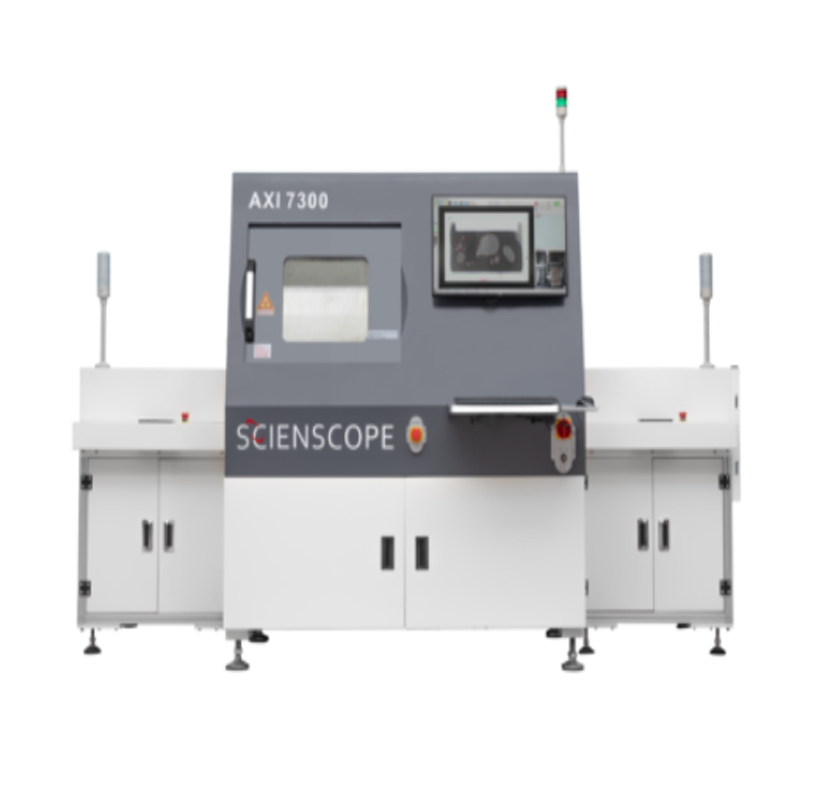

Scienscope AXI 7300

The AXI 7300 is our the most technologically advanced X-Ray Inspection System. As with all X-SCOPE platforms, it includes every advanced s/w tool required for a wide variety of applications.

Nikon XT V 160 Electronics X-ray Inspection

The AXI 7300 is our the most technologically advanced X-Ray Inspection System. As with all X-SCOPE platforms, it includes every advanced s/w tool required for a wide variety of applications.

Nikon MCT225 for Metrology CT

MCT225 efficiently measures internal and external geometry without reference measurements and damaging the sample. With fifty years’ CMM experience and twenty five years’ X-ray experience, our pedigree for reliable high quality Metrology CT is second to none.

Nikon XT H 450 for CT Inspection of Blades and Castings

The XT H 450 sets a new reference for turbine blade measurement and NDT of small to medium castings. At the core of this powerful equipment is a 450kV micro-focus source, providing superior resolution and accuracy. The curved linear array detector optimizes the collection of X-rays by eliminating scatter phenomena that typically corrupt 2D radiographs of blades and other metal parts.

Nikon XT H 320 Industrial CT Scanning

The XT H 320 features a more powerful microfocus X-ray source that is able to run highly accurate inspection on dense industrial objects. The system consists of a 320 kV microfocus source delivering up to 320 W of power. As the X-ray spot size of these sources is orders of magnitude smaller compared to minifocus sources, end users benefit from superior resolution, accuracy and a wider array of measurable parts.

Nikon XT H 225 / XT H225 ST Industrial CT Scanning

Detailed capture and measurement of internal component and assembly features is often vital for quality control, failure analysis and material research. XT H 225 offers a powerful micro-focus X-ray source, a large inspection volume, and high X-ray and CT imaging resolution. XT H 225 suits a wide range of applications, including inspection of small castings, plastic parts as well as material research.

- X-Ray Parts Counters

AXC-800III

The Scienscope Award-Winning AXC-800III is the third generation of the revolutionary X-ray component counter. By utilizing the state-of-the-art X-Ray technology and intelligent AI algorithm, the AXC-800III captures the images of the components inside the reels and uses AI to count the quantities.

Scienscope AXI-5100c II

The Scienscope AXI-5100c II is the most advanced, automated component counting system in the world which features an automatic loader and label printer.

AXC-300-3 Plus

The AXC-800 III Plus makes inventory management and component counting faster, accurate and easier than ever before. The new upgrade comes with a conveyor and more.

AXC-300-3

The AXC-800 III makes inventory management and component counting faster, accurate and easier than ever before.

VisiConsult X-Ray Counter

From standalone to inline, the XRHCount is the easiest and fastest way to revolutionize the SMD component management.

- Conformal Coating Inspection

Neptune T

Neptune T is suitable for applications from lab testing to industrial inspection. It has a thickness measurement of transparent and semi-transparent materials, and classifies real signals from raw images.

Neptune C

Neptune C solves the obsolescence challenge. It is the industry’s only future-proof True3D solution for transparent material inspection.

Neptune C+

Revolutionary True 3D In-line Dispensing Process Inspection (DPI) with a Thickness Measurement Solution based on Patented Technologies.

Neptune USX

Using patented L.I.F.T. technology for rapid material thickness measurement, the award-winning Neptune inspection platform revolutionized in-line dispensing process inspection.

Your Vision, Our Expertise: Tailored Solutions for Every Need.

For a customized quotation and additional information on how our solutions can enhance your manufacturing process, please contact us today. Our team is ready to discuss your specific needs, provide expert guidance, and help you select the best options to achieve optimal results for your project. Reach out to explore how we can support your goals with tailored solutions and industry-leading expertise.