Our material handling solutions streamline the movement and organization of components, reducing bottlenecks and ensuring a smooth production flow.

With automated and reliable handling systems, we help increase throughput and minimize manual intervention, allowing faster, more efficient manufacturing processes.

Designed to adapt to various production environments, our material handling products easily integrate with existing equipment, providing a scalable solution for evolving manufacturing needs.

- Conveyor Series

Vacuum Loader – Edge

Using “Edge vacuum pad”, this unit unstacks bare boards one by one

PCB Cleaner – Vacuum+Sticky roller

PCB cleaner vacuum+sticky roller removes dust and particle on a PCB by vacuum, sticky roller and ionizer while being transferred to next process.

Gate Conveyor – Telescope

In the middle of SMT line, this unit allows operators to pass through the line, without interrupting PCB flow.

Gate Conveyor – Down/Up

This is a device that allows workers to pass through the production line without any interruption to the flow of PCBs in the SMT line.

Vertical Turn

This device rotates the PCB 180 degrees for double-sided operation in the SMT line.

Horizontal Turn

This unit turns PCBs' flow direction clockwise and counter clockwise

Shuttle Conveyor

This unit can merge a few production lines into a single one or separate one a single line into a few multiple ones.

Elevator Unit – Sky Line

The sky line can be used for operators’ passage in SMT lines.

Elevator Unit – Pallet Return Line

The pallet return line provides automated return of empty pallets. It is completely automated with PLC control and can convey pallets efficiently and quickly

YJ Link

SMT Automation Process which is a specialized service of YJ LINK and Visual Support, we are providing prompt and accurate service as well as customer needs.

- Loaders and Unloaders

Magazine Loader

Located at the first stage of SMT line, this unit transfers PCBs stacked in a magazine rack to the downstream machine using a pneumatic pusher one by one.

Magazine Loader - All types (Chain)

Located at the final stage of the SMT line, this unit stacks PCBs in an empty magazine rack using a pneumatic pusher one by one. The conveyor part and the inside of the lifter are designed to accommodate racks of various sizes

Shuttle Loader – AGV (2-racks / 3-racks)

Located at the first stage of SMT line, this unit consists of a coupling of a single shuttle and a rack part then transfers PCBs stacked in a magazine rack to the downstream machine using a puller mounted on the single shuttle

Magazine Unloader

Located at the final stage of SMT line, this unit stacks PCBs in an empty magazine rack using a pneumatic pusher one by one.

Magazine Unloader – All type(Bar)

Located at the final stage of the SMT line, this unit stacks PCBs in an empty magazine rack using a pneumatic pusher one by one. The conveyor part and the inside of the lifter are designed to accommodate racks of various sizes.

Shuttle Unloader (2-racks / 3-racks)

Located at the first stage of SMT line, this unit consists of a coupling of a single shuttle and a rack part then transfers PCBs stacked in a magazine rack to the downstream machine using a puller mounted on the single shuttle

- Stackers

Destacker - Knife

Using “Knife Cylinder”, this unit unstacks bare boards one by one.

Destacker - Clamp

Using “Side Clamp”, this unit unstacks bare boards one by one.

Destacker - Clamp(Batch)

With the buffer station designed to accommodate more PCB batches, operators may utilize time more efficiently.

Vacuum Loader - Edge

Using “Edge vacuum pad”, this unit unstacks bare boards one by one

Stacker

Using cylinder, it lifts up a bare board for stacking up as an unloader of offline laser marking machine.

Destacker - Knife

Using “Knife Cylinder”, this unit unstacks bare boards one by one.

Destacker - Clamp

Using “Side Clamp”, this unit unstacks bare boards one by one

Destacker - Clamp(Batch)

With the buffer station designed to accommodate more PCB batches, operators may utilize time more efficiently.

- Buffers

Combi - Magazine

The equipment is located after the SPI / AOI, which allows simultaneous PCB buffering and NG PCB loading.

Combi – Rack

This equipment is located between SMT machines to improve working efficiency by buffering PCB.

Tower

This unit is located between SMT machines to improve working efficiency by buffering.

Tower – Cooling

This unit is located after the oven to decrease the temperature of the PCB and provide buffering.

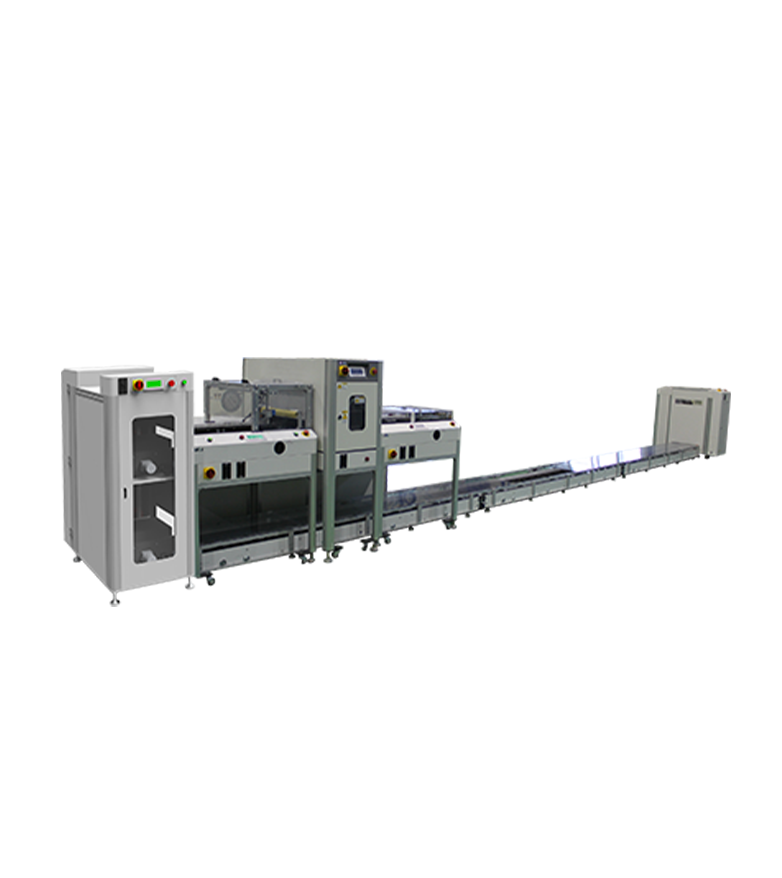

Tower + Conveyor – Cooling

This unit is located after the oven to decrease the temperature of the PCB and provide buffering.

Tower + NG Conveyor

This unit is located after SPI/AOI machine to inspect NG boards in the line. The operator can call NG boards from the rack onto the 2nd layer of the conveyor to inspect them visually while the GOOD boards are being passed.

- Laser Markers

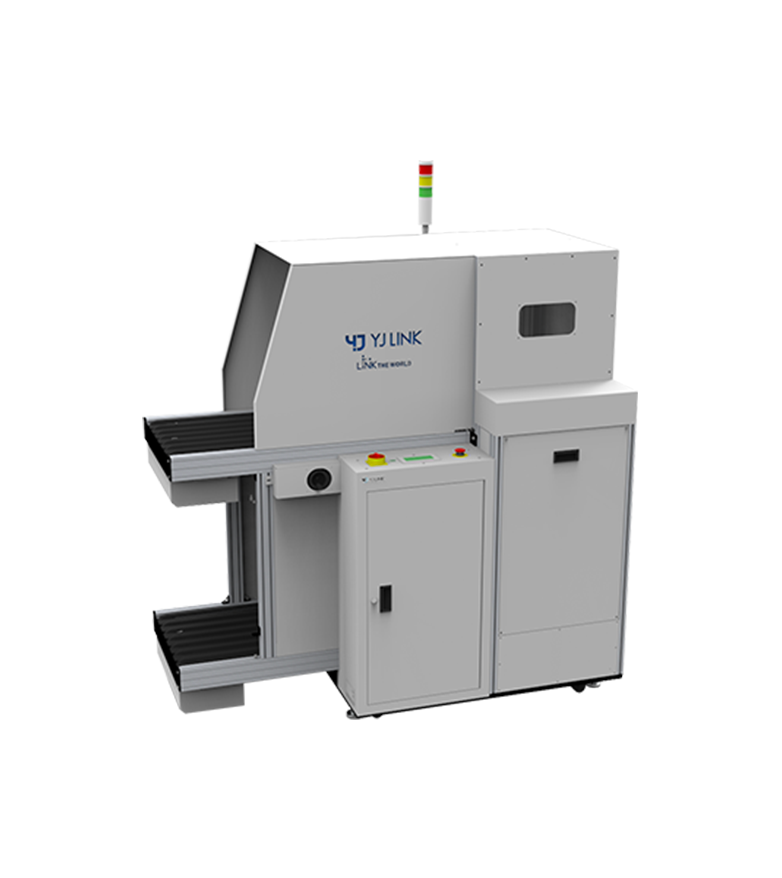

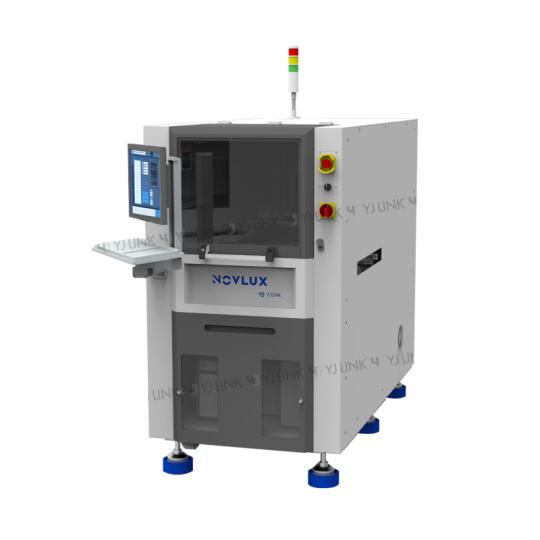

YJ-Link - Laser Marking Machine NOVLUX CO2

The NOVLUX CO2 laser marker engraves 1D/2D barcodes, logos, and characters on the surface of a PCB or an object without physical or chemical damage with a CO2 head.

Barcode Scanning Conveyor (Single / Both)

Automatic: automatic desoldering, placement and soldering of SMT components.

PCB Cleaner – Vacuum + Sticky roller

PCB cleanervacuum+sticky roller removes dust and particle on a PCB by vacuum, sticky roller and ionizer while being transferred to next process.

- Routers

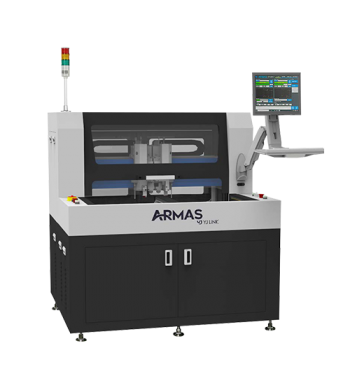

ARMAS Router – BRONZE

This equipment is a cutting device that utilizes spindle bits to cut assembled PCBs into individual modules.

ARMAS Router – SILVER

This equipment is a cutting device that utilizes spindle bits to cut assembled PCBs into individual modules.

ARMAS Router – PLATINUM

This equipment is a cutting device that utilizes spindle bits to cut assembled PCBs into individual modules.

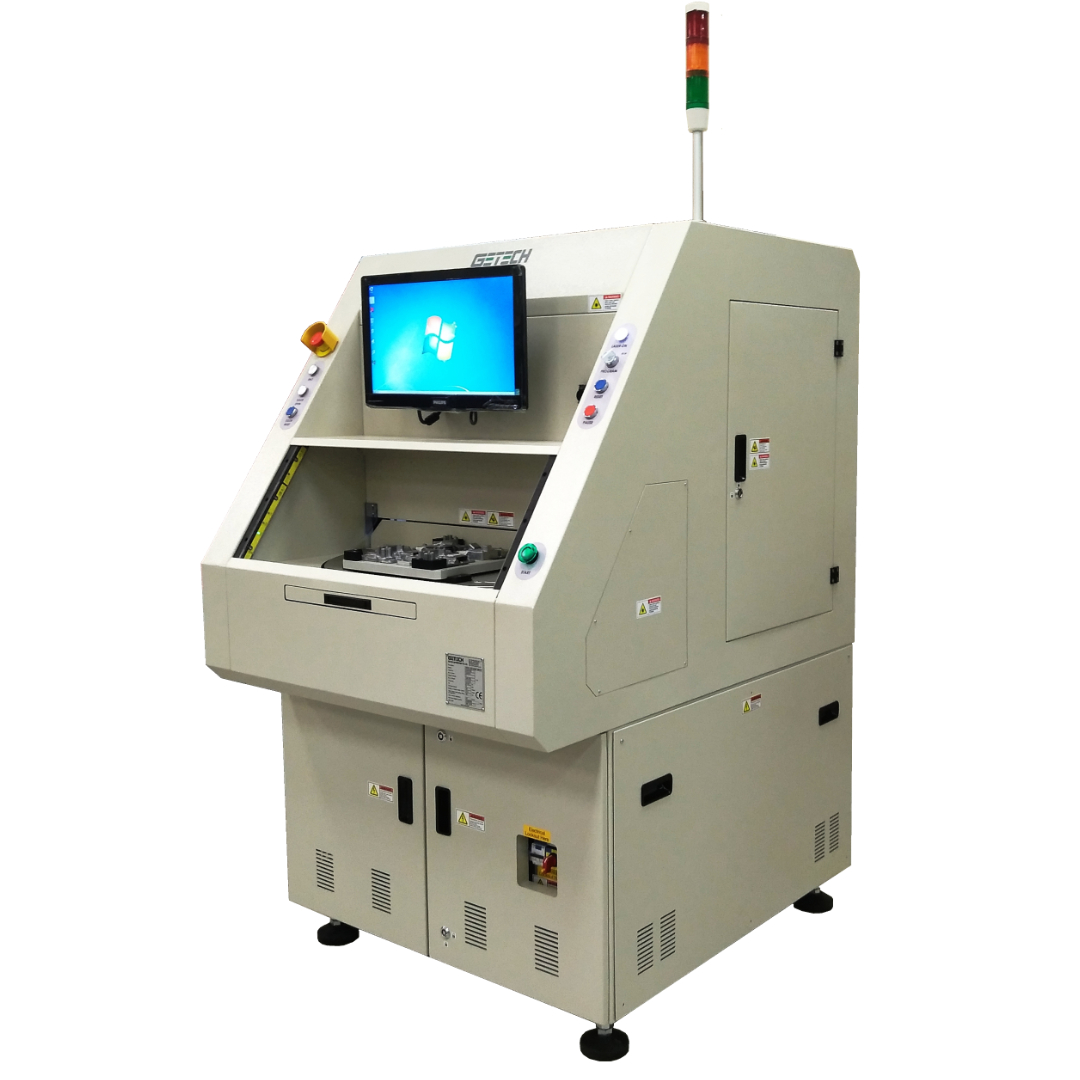

Getech GAR1200

Inline Automatic Router Designed for high-speed routing and high volume production of PCB panels (350mm x 310mm)Inline Automatic Router Designed for high-speed routing and high volume production of PCB panels (350mm x 310mm)

Getech GAR1200L

Large Inline Automatic Router Designed for high-speed routing and high volume production of large PCB panels (450mm x 310mm)

Getech GBR

Inline Bottom Router Designed for routing of large PCB panels (600mm x 400mm)

Getech GBR MAX

Large Inline Bottom Router Designed for routing of large PCB panels (1200mm x 400mm)

Getech GLMS

Laser Marking System Designed to laser mark large format heavy PCBs, and ultra-thin and flexible PCBAs

Getech GLRH

Laser Rotary Handler Designed to laser mark aluminum base plates

Getech GLSS

Laser Singulation System Designed for high-speed laser depaneling and high-volume production of rigid and semi-flexible PCB panels

Getech GSNL

PCB Sorting and Tray Loading System Designed for high-speed unloading of PCB boards and automatic tray handling

Getech GSR1200

Inline Automatic Router Designed for high-speed routing and high volume production of PCB panels (350mm x 350mm)

Getech GSR1200E

Semi-Automatic Router Designed for high-speed routing and high volume production of large PCB panels (500mm x 450mm)

Getech GSR1280

Semi-Automatic Router Designed for high-speed routing and high volume production of large PCB panels (500mm x 500mm)

Getech GSR1280E

Semi-Automatic Router Designed for high-speed routing and high volume production of large PCB panels (610mm x 610mm)

Getech ALP

Automatic Labeling Machine Designed for high-speed label transfer of pre-printed labels for different sizes of PCB panels

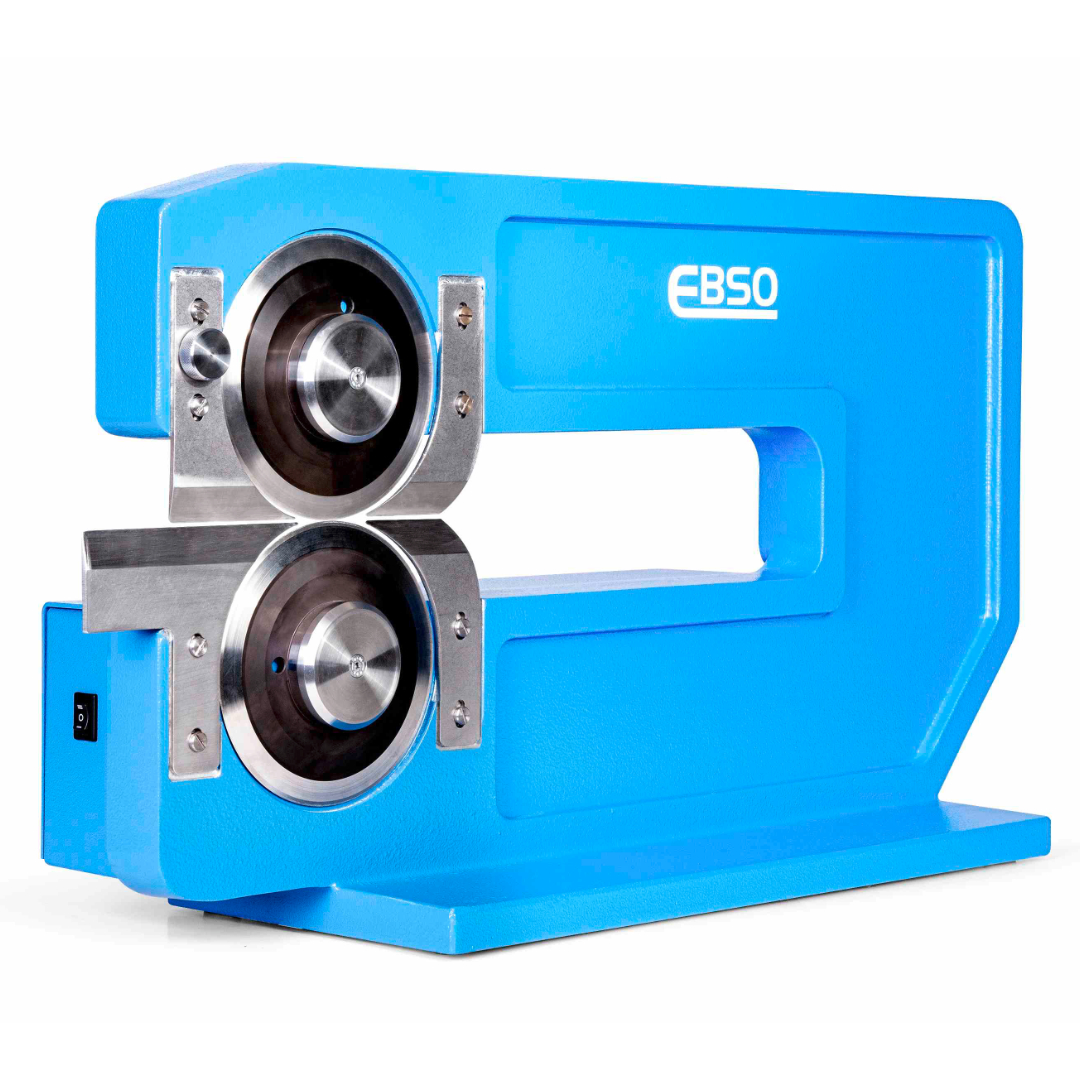

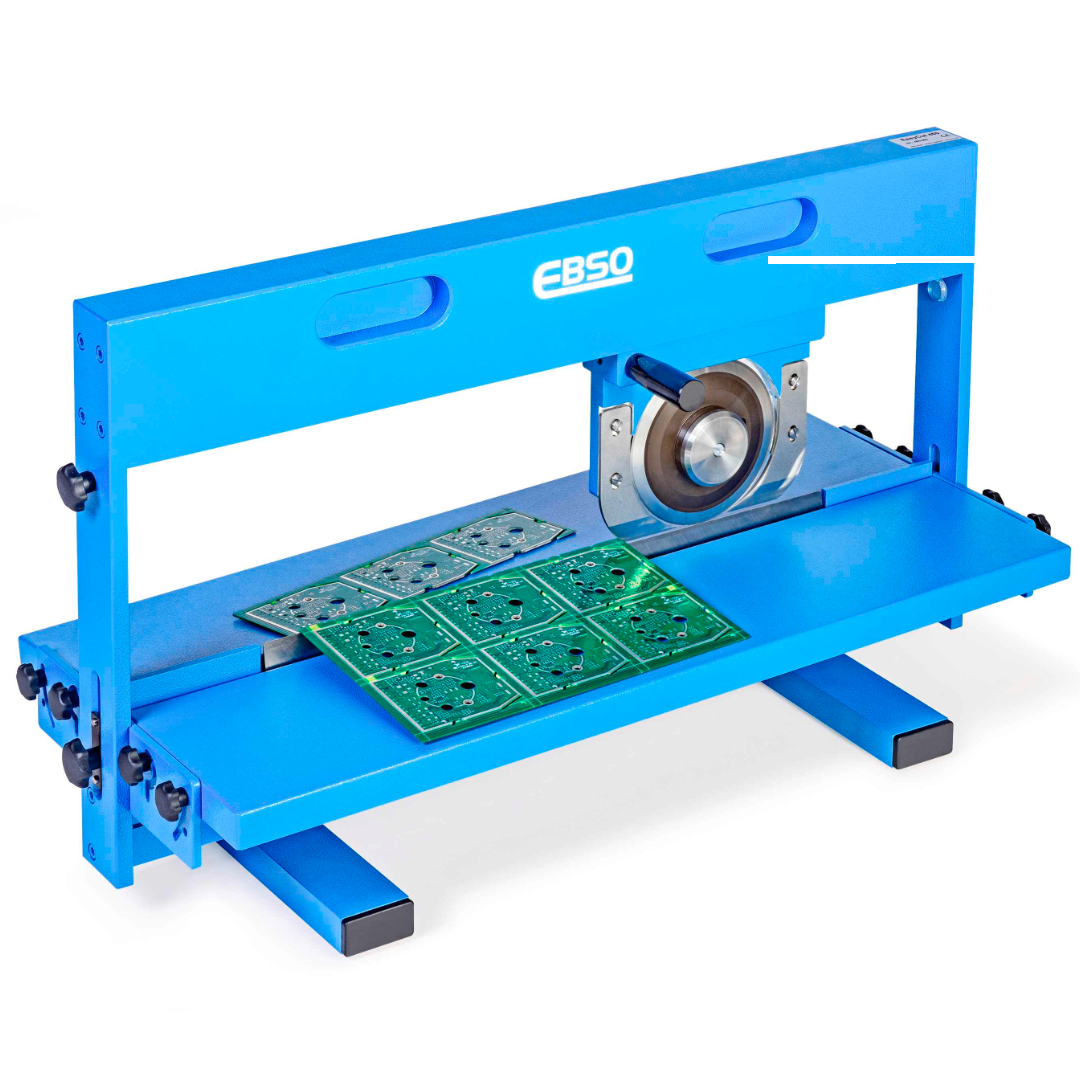

EBSO EasyCut 100

Nibbler for Tab-routed PCB Boards Separates routed PCB boards carefully and economically

EBSO EasyCut 300/300M

Depanelizer for Square or Rectangular Boards EBSO 300/300M is offered in manual (300) and motorized (300M) options

EBSO EasyCut 450

Depanelizer with Circular or Linear Blade Options For PCBs up to 450mm (17.7″) in length

- Magazine Racks

Magazine Rack

Magazine rack is an accessory that can store PCBs for an SMT production line. The product comes in 4 sizes - M, L, XL and 2XL.

Your Vision, Our Expertise: Tailored Solutions for Every Need.

For a customized quotation and additional information on how our solutions can enhance your manufacturing process, please contact us today. Our team is ready to discuss your specific needs, provide expert guidance, and help you select the best options to achieve optimal results for your project. Reach out to explore how we can support your goals with tailored solutions and industry-leading expertise.