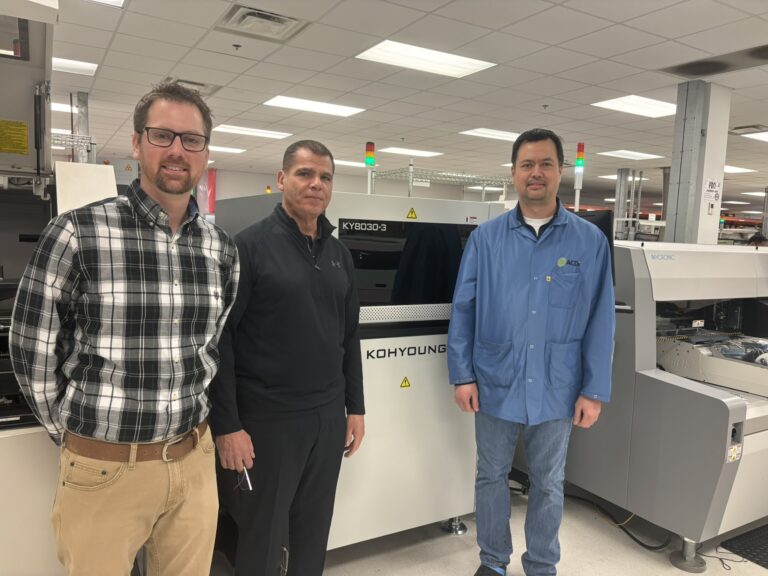

Our through-hole mounting solutions ensure precise component placement and strong mechanical bonds, ideal for applications demanding high durability and reliability.

Using state-of-the-art equipment, we deliver accurate and consistent through-hole mounting, enhancing performance and reducing production errors

We customize our through-hole solutions to meet the rigorous standards of industries like automotive, aerospace, and industrial electronics, ensuring long-lasting connections in critical applications.

- Screen Printing

Panasonic SPG2

The SPG2 is the next-generation of high accuracy and high density screen printing. Forged from the key principles of the first-generation SPG, this new solution enhances automation through labor-saving functions.

Panasonic SPV-DC

The SPV-DC enables high efficiency dual lane production in a compact package. Achieve compact dual-lane and high-efficiency production while cutting operating costs. Paperless cleaning technology allows for improved overall quality in an integrated line using Panasonic mounters.

Panasonic SPV

The revolutionary SPV transforms the traditional production model by supporting a myriad of options to print multiple 350x300mm (M-size) boards simultaneously. Complementing the versatility is a feature set rich with changeover options and an inherent print-clean cycle of 10 seconds.

Panasonic SPG

Panasonic's SPG high-speed screen printing machine is the ultimate solution for lean SMT manufacturing. Our original uni-floating printing method reliably delivers the right amount of solder in the right form with high-speed snap-off and reduced solder waste. The SPG's intuitive interface enables the operator to set parameters based on production requirements-making print condition adjustments nearly automatic.

NPM-GPL

The NPM-GP/L is the newest screen printer added to the NPM-G Series that optimizes Overall Equipment Effectiveness and enhances overall line performance.

- SMT Placement

Panasonic NPM-D3 SMT

The evolutionary Panasonic NPM-D3 continues in the steps of its award-winning predecessor with interchangeable dispensing, placement, and inspection heads; however, new enhancements further increase productivity. The NPM-D3 now handles a component range spanning 03015mm microchips to massive 100x90mm components up to 28mm tall, as well as Package on Package applications.

Panasonic NPM-W2

The new NPM-W2 amplifies the original NPM-W capabilities with a 10% throughput boost and 25% more accuracy. It also integrates new innovations like our incomparable Multi Recognition Camera. Combined, these features extend the component range down to the 03015mm microchip, yet preserve capability up to 120x90mm components up to 40mm tall and nearly 6” long (150mm) connectors.

Panasonic NPM-TT2

The NPM-TT2 (Next Production Modular-Twin Tray II) platform represents the next generation in twin tray modular production from Panasonic’s award-winning NPM platform—ideal for any mix.

Panasonic NPM X-Series

The NPM X-Series is designed around a stiff frame, constructed of durable materials and built to last. Available in single-, dual- and quad-beam variants. With onboard dual-drive linear motors complimented by light and rigid beam architecture, the NPM X-Series introduces new industry-leading options; Linear servo motors with dual-drive Y and High Resolution linear scales in each motor.

Optimizing Precision and Productivity in Every SMT Assembly

- Reflow Solder

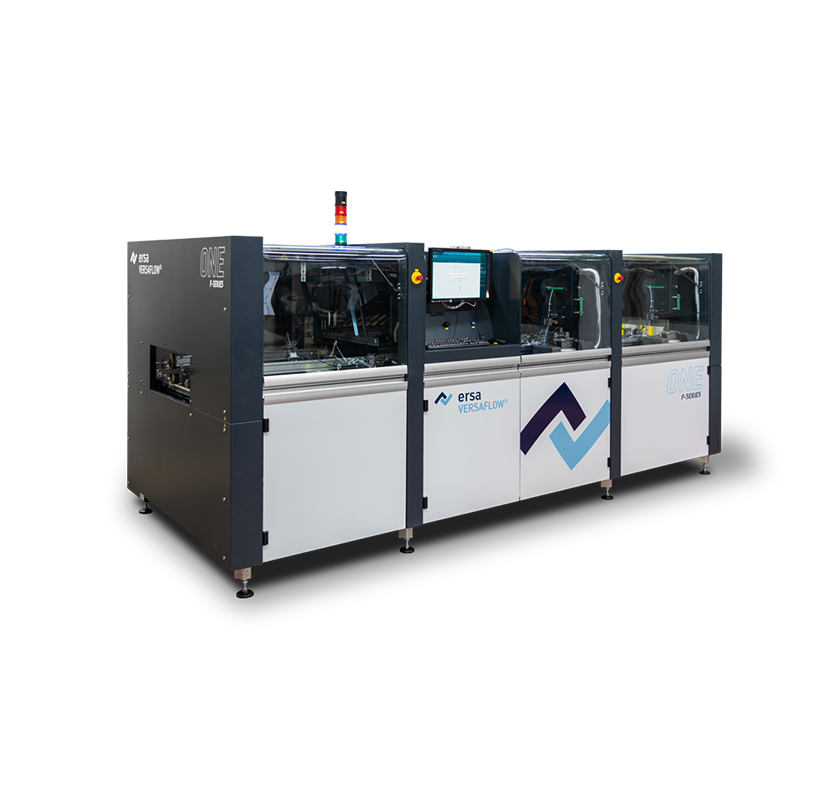

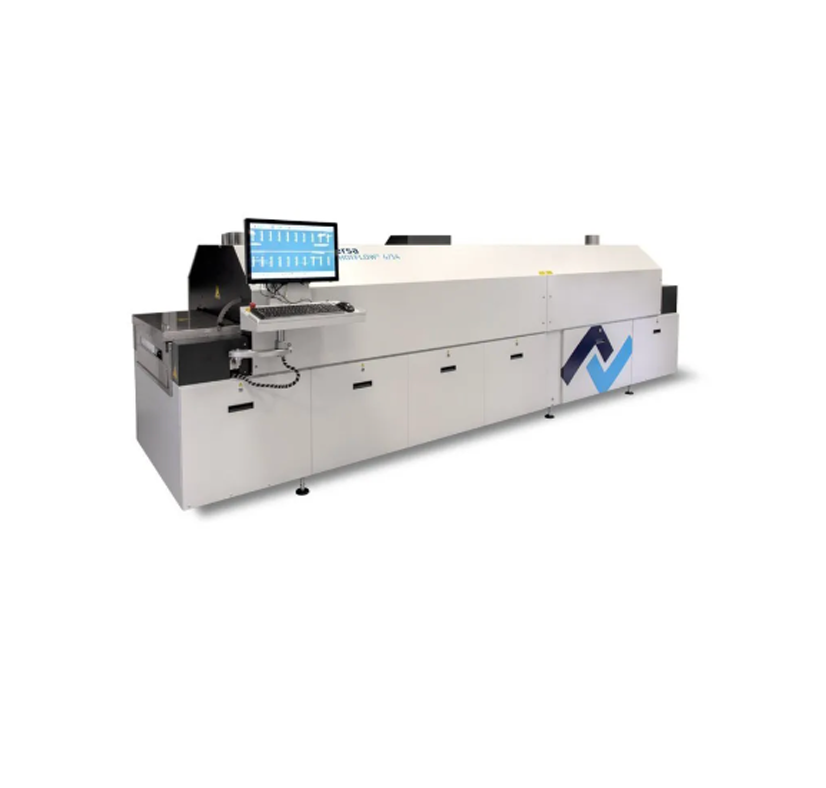

VERSAFLOW ONE

Your entry into the excellence class of Selective Soldering: Top quality with a compact footprint - the selective soldering machine VERSAFLOW ONE is the new entry into the portfolio of Ersa VERSAFLOW inline selective soldering systems. The system combines proven Ersa DNA and customer-oriented option structure with high availability at extremely attractive acquisition as well as operating costs.

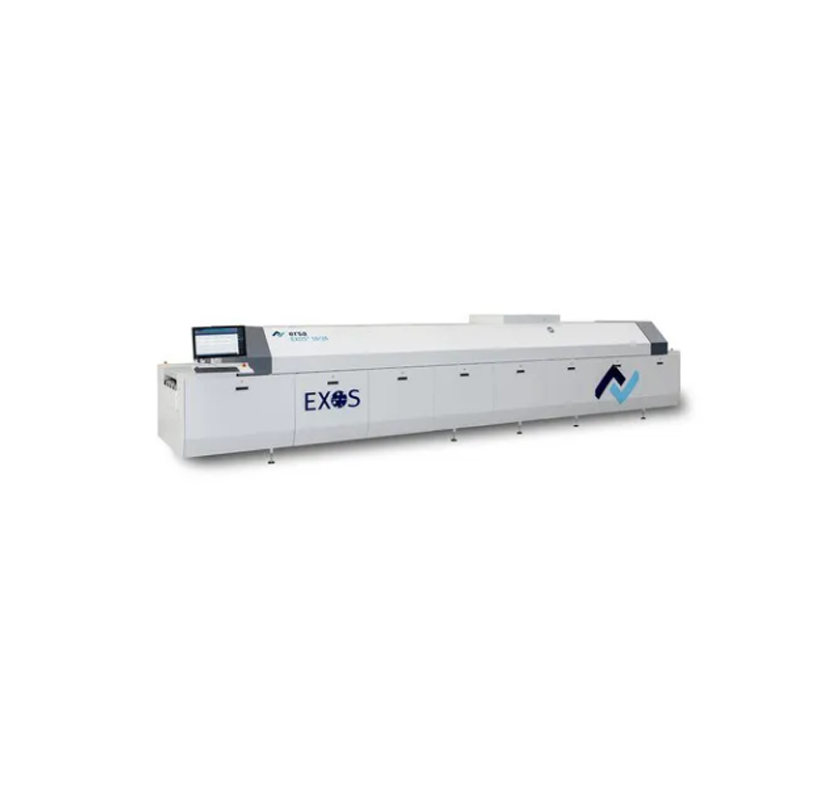

Kurtz Ersa EXOS 10/26

With the EXOS 10/26, Ersa presents a convection reflow soldering system with 22 heating and four cooling zones as well as a vacuum chamber after the peak zone, with which the void rate can be reduced by 99%. This is achieved by relying on technologies proven thousands of times in HOTFLOW models, such as heating and cooling zones or the intuitive, award-winning interface.

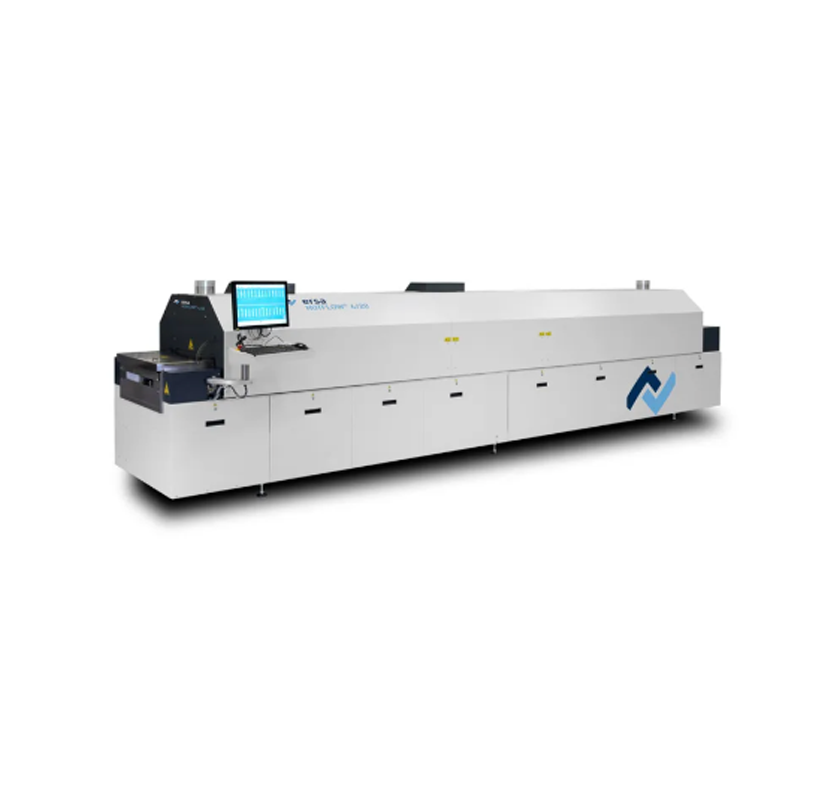

Kurtz Ersa Hotflow 4/26

The Ersa HOTFLOW 4/26 Reflow Soldering System is of robust design and manufactured entirely from steel, welded air-tight, powder coated and with interior electric cabinet and a PC operating terminal. Features include the motorized hood opening, quick-change convection heater cassettes, multi-level process gas cleaning and a powerful, high-performance cooling zone.

Kurtz Ersa Hotflow 4/20

The Ersa HOTFLOW 4/20 Reflow Soldering System is of robust design and manufactured entirely from steel, welded air-tight, powder coated and with interior electric cabinet and a PC operating terminal. Features include the motorized hood opening, quick-change convection heater cassettes, multi-level process gas cleaning and a powerful, high-performance cooling zone.

Kurtz Ersa Hotflow 4/14

The Ersa HOTFLOW 4/14 Reflow Soldering System is of robust design and manufactured entirely from steel, welded air-tight, powder coated and with interior electric cabinet and a PC operating terminal. Features include the motorized hood opening, quick-change convection heater cassettes, multi-level process gas cleaning and a powerful, high-performance cooling zone.

Kurtz Ersa Hotflow 4/8

The Ersa HOTFLOW 4/08 Reflow Soldering System is of robust design and manufactured entirely from steel, welded air-tight, powder coated and with interior electric cabinet and a PC operating terminal. Features include the motorized hood opening, quick-change convection heater cassettes, multi-level process gas cleaning and a powerful and effective cooling zone.

Kurtz Ersa Hotflow 3/20

The Ersa HOTFLOW 3/20 Reflow Soldering System is of robust design and manufactured entirely from steel, welded air-tight, powder coated and with interior electric cabinet and a PC operating terminal. Features include the motorized hood opening, quick-change convection heater cassettes, multi-level process gas cleaning and a powerful and effective cooling zone.

Kurtz Ersa Hotflow 3/20e

The Ersa HOTFLOW 3/20e Reflow System is of robust design and manufactured entirely from steel, welded air-tight, powder coated and with interior electric cabinet and a PC operating terminal. Features include the motorized hood opening, quick-change convection heater cassettes, multi-level process gas cleaning and a powerful and effective cooling zone.

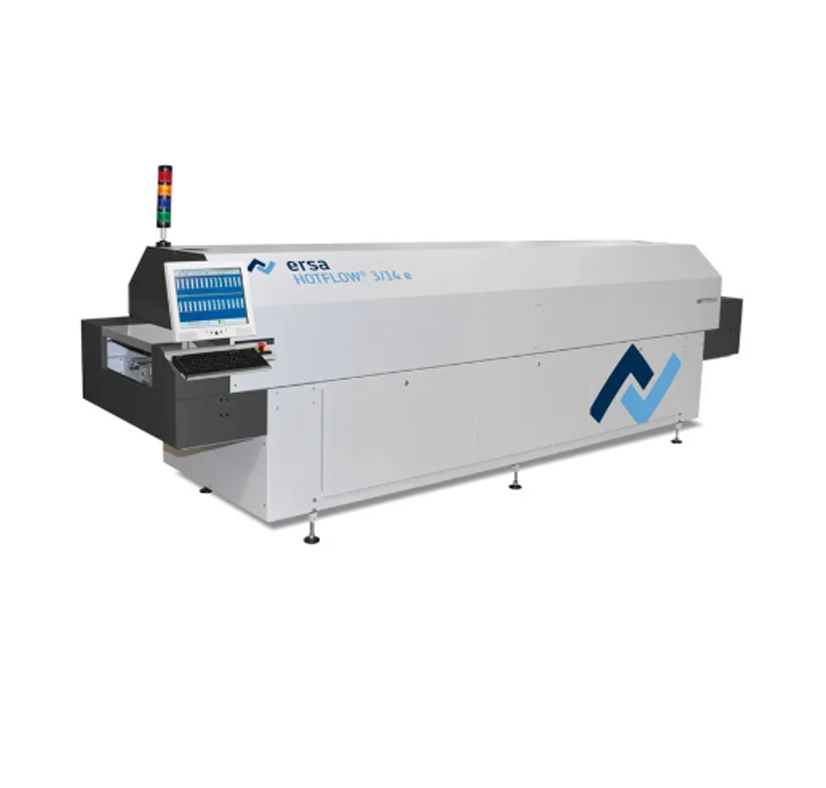

Kurtz Ersa Hotflow 3/14

The Ersa HOTFLOW 3/14 reflow system is of robust design and manufactured entirely from steel, welded air-tight, powder coated and with interior electric cabinet and a PC operating terminal. Features include the motorized hood opening, quick-change convection heater cassettes, multi-level process gas cleaning and a powerful and effective cooling zone.

Kurtz Ersa Hotflow 3/14e

The Ersa HOTFLOW 3/14e Reflow System is of robust design and manufactured entirely from steel, welded air-tight, powder coated and with interior electric cabinet and a PC operating terminal. Features include the motorized hood opening, quick-change convection heater cassettes, multi-level process gas cleaning and a powerful and effective cooling zone.

- Our Principles

Guided by Excellence: Principles that Drive Innovation and Integrity

Industry Leaders Committed to Excellence

Our principles center on setting the benchmark for innovation and expertise in the electronics manufacturing industry. With decades of experience, we leverage our deep knowledge and strategic partnerships to deliver high-quality, reliable solutions that drive industry progress.

Pioneering the Path to Smart Manufacturing

At the forefront of technological advancements, we prioritize smart manufacturing principles that integrate automation, real-time data, and IoT technology. Our approach ensures our clients stay competitive in a rapidly evolving landscape, achieving efficiency, flexibility, and adaptability in every production process.

Quality Assurance for Reliable Manufacturing

Quality assurance is at the heart of our operations. Our commitment to rigorous standards and continuous improvement guarantees that every product meets the highest levels of reliability and durability. From design to delivery, our focus on quality ensures consistent, dependable results across all manufacturing stages.

- Conformal Coating

SCS PrecisionCoat VI

The SCS PrecisionCoat VI provides more than a dependable layer of protection; it's a total system solution that ensures accuracy, repeatability and high throughput for a wide range of automated material applications.

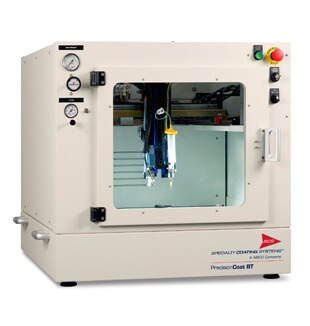

SCS PrecisionCoat BT

Designed for companies looking to automate their time-intensive manual coating and dispensing processes, or those who would like to have additional coating capacity in their laboratory or on their production floor, the new PrecisionCoat BT improves accuracy, productivity and efficiency in a highly reliable, compact unit.

SCS Precision UVC

The SCS Precision UVC offers full-spectrum UV curing in perfect integration with the SCS Precisioncoat.

SCS Precisioncure TC

Curing materials by convection heat has been made easier with the SCS Precisioncure TC. Designed for maximum performance, the system features a single chamber design and is available with 3 or 7 heating zones to cure a wide variety of materials. Each zone is heated via top forced convection technology and features independent closed-loop blower speed control, which ensures stable thermal performance.

SCS G3 Spin Coater Series

Compact yet packed with performance features, the SCS G3 Spin Coater series combines precision with control for highly effective coating applications development. Adding to its performance is a number of optional features.

SCS 6800 Spin Coater Series

The SCS 6800 Spin Coater Series offers researchers efficiency and accuracy they can rely on.

SCS Multi-Dispense System

When more than one material is part of a coating application, one name delivers consistent performance. SCS Multi-Dispense gives you four dispense modules to make the coating application and development process even more efficient.

SCS P-3201

The SCS P-3201 Dip Coating System offers performance and reliability to manufacturers who need in-house dip coating capabilities.

SCS PL-3201

The SCS PL-3201 tabletop Dip Coater has all the features found in our P-3201 Dip Coater, plus a number of optional features that bring added performance and functionality to the process of dip coating.

SCS Ionograph® SMD V

Dynamic testing of ionic contamination is a widely approved and followed standard. So, too, is the equipment that makes it possible — SCS Ionograph®. Available in different models, the SCS Ionograph is the industry standard of testing technology.

SCS Ionograph® BT

SCS Ionograph® BT Series ionic contamination test systems offer efficient and accurate testing to meet the needs of any lab or manufacturer.

SCS Omegameter Series

The SCS Omegameter is an industry standard for ionic testing of printed circuit boards and assemblies.

SCS PDS 2010 Labcoter® 2

The SCS Labcoter® gives university and R&D laboratories the best in Parylene coating technology, in a compact, portable system, enabling researchers to develop and design with the polymer Parylene.

SCS PDS 2060PC

The SCS PDS 2060PC is designed to precisely apply Parylene conformal coatings in a production setting.

Principles that Drive Manufacturing Excellence

Your Vision, Our Expertise: Tailored Solutions for Every Need.

For a customized quotation and additional information on how our solutions can enhance your manufacturing process, please contact us today. Our team is ready to discuss your specific needs, provide expert guidance, and help you select the best options to achieve optimal results for your project. Reach out to explore how we can support your goals with tailored solutions and industry-leading expertise.